MLC - Metal Like Ceramic

Where ceramic meets steel

Learn more about the new patented material,

which combines the advantages of ceramic and steel for the first time.

MLC Composite Ceramic for Advanced Hybrid Bearing and Component Applications

The MLC composite ceramic

was originally pre-developed by one of the world’s largest bearing corporations specifically for use in hybrid rolling bearings and was brought to production maturity by us.

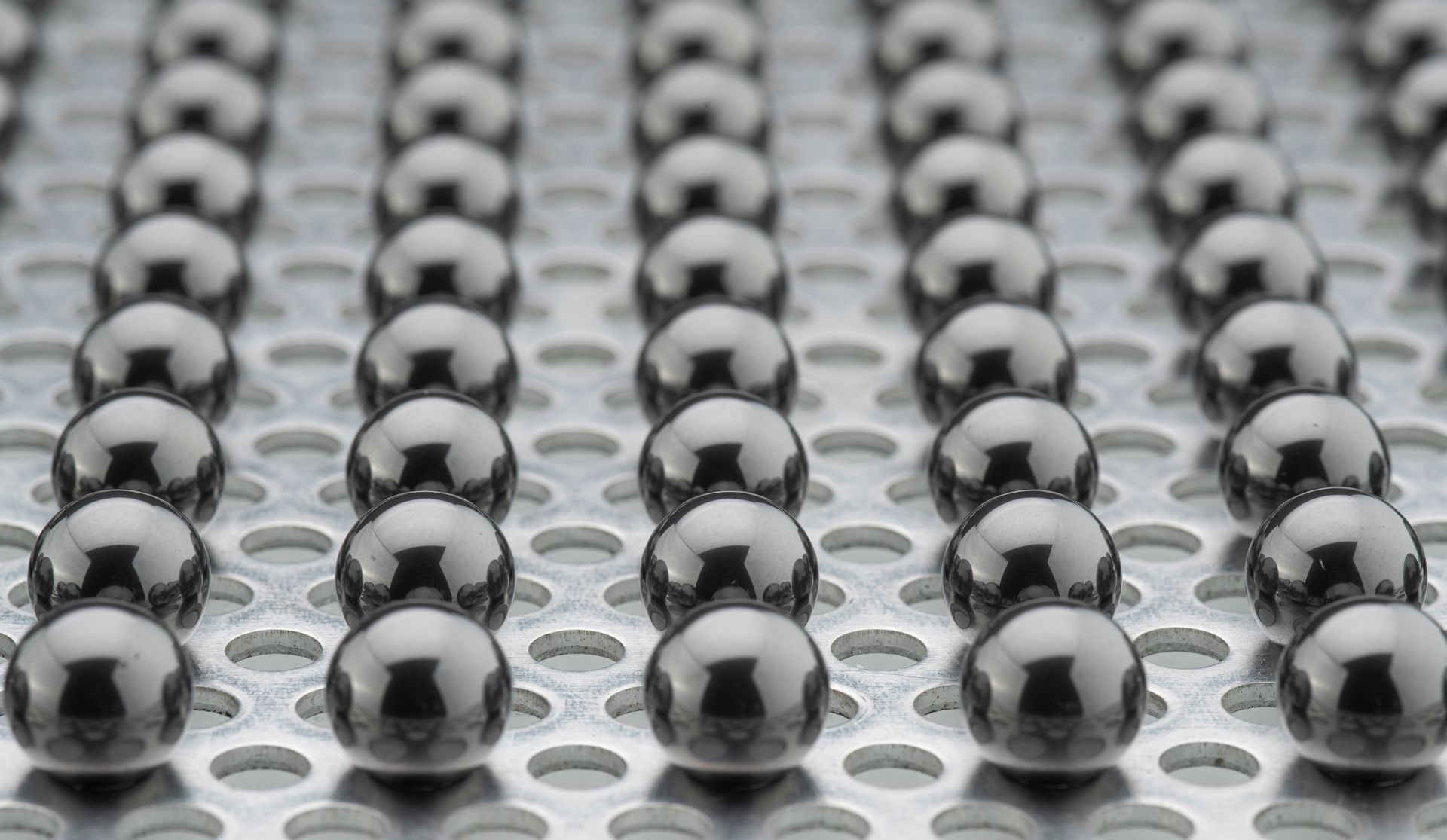

We develop and manufacture ceramic rolling elements (balls, cylindrical rollers, needle rollers), primarily in the diameter range of 1.5 mm to 20 mm. In addition, we produce a wide variety of ceramic components according to your technical drawings.

Ceramic bearing balls

can be manufactured in G5 quality, and ceramic cylindrical rollers

or needle rollers can be produced in G1/G2 quality.

Furthermore, we also develop and produce ceramic drawing rings

and dies, ceramic plain bearing

components, ceramic nozzles, ceramic valve disks, and much more.

Our composite ceramic (MLC) was initially developed primarily for use in rolling bearings. However, it has since become evident that the unique material properties of MLC ceramics

— with characteristics that lie between steel and conventional ceramics (see table) — also make them suitable for a wide range of other technical components.

The base materials of our composite ceramic (MLC) are processed in-house

through several stages into a plastic-like consistency, making them easy and cost-effective to machine. This allows for precise, near-net-shape,

and affordable forming. During the subsequent heat treatment, volumetric shrinkage is only about 5–8%, which is already taken into account during the initial forming process.

For high-precision functional surfaces, our composite ceramic can undergo final hard machining (grinding, honing). Silicon carbide can be used for fine grinding, which makes the finishing process significantly more economical compared to standard ceramics such as SiC or Si₃N₄.

For the first time, our composite ceramic enables the advantages of ceramic materials to be used in components that, due to their geometric complexity, were previously only cost-effective to produce in steel. We are already able to cost-effectively manufacture such geometrically diverse components even in small series.

Advantages

- Near-net-shape production

- Cost-optimized processing

- Pore-free production

- High sliding capability

(without lubricants) - High freedom of design

- High temperature resistance

-

- Capability of high loads

- High Hardness

- 50 % reduction in weight

(compared to steel) - Production in small series

The material

| Material characteristics | Silizium-Nitrid | MLC | bearing steel |

|---|---|---|---|

| Freedom of design | -- | ++ | ++ |

| Mechanical machinability | -- | + | ++ |

| Corrosion resistance | ++ | ++ | -- |

| wear resistance | ++ | ++ | - |

| Maximum operating temperature / °C | 800 | 800 | 200 |

| Rolling strength / MPa | >2.000 | >2.000 | |

| Young's modulus / GPa | 320 | 200 | 210 |

| Hardness / HV10 | 1.400 | 1.000 | 750 |

| Fracture toughness / MPa√m | 5 | 4 | 15 |

| 4-point bending strength / MPa | 600 | 400 | (2.400) |

| Porosity / % | < 1 % | < 1 % | |

| Density / (g/cm3) | 3,2 | 3,6 | 7,8 |

| Specific electrical resistance / Ωm | 1e12 | 1e-3 | 1e-7 |

| Thermal expansion coefficient / (10-6/K) | 3,5 | 8 | 11,5 |

| Thermal conductivity / (W/mK) | 30 | 15 | 45 |

Fields of application

Possible applications are e.g:

- Clean room & vacuum, corrosive and polluted environments

- bad lubrication conditions

- Printed circuit board and semiconductor manufacturing

- food, textile, welding

- Electronics & mechatronics

- Measurement & testing technology, copier

- Lightweight construction, medical technology, extruders, injection molding machines, ...